Prediction of Build Geometry for DED using Supervised Learning Methods on Simulated Process Monitoring Data

Charles Snyers, Julien Ertveldt, Jorge Sanchez-Medina, Zoé Jardon and Jan Helsen

Published in Journal of Laser Applications, 2021

Find the full article here.

Abstract

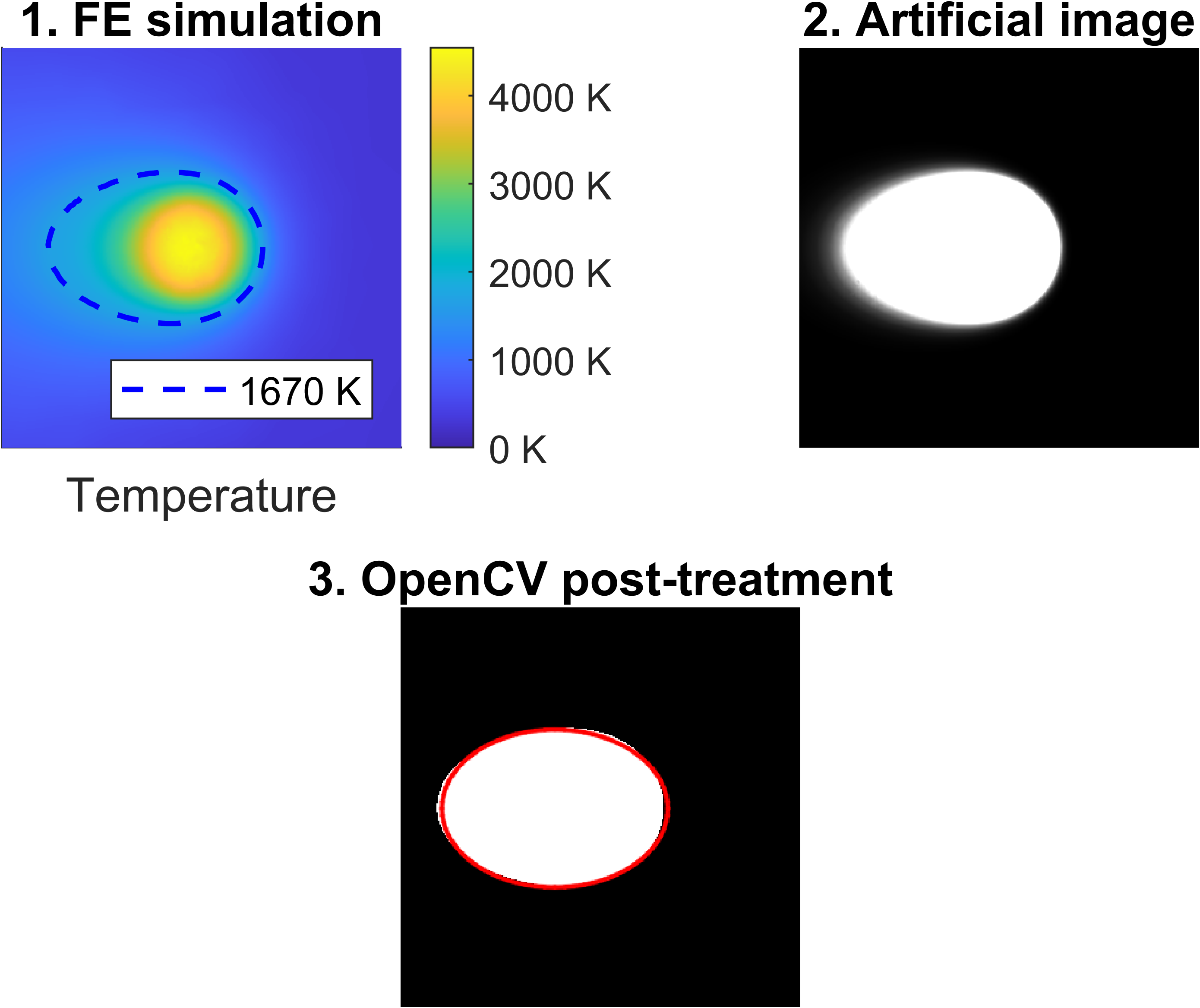

One of today’s ongoing challenges in directed energy deposition (DED) is controlling the geometry and material properties of parts. This manufacturing process is complex and nonlinear due to multiple physical phenomena at play and is therefore hard to model analytically. Machine learning (ML) on the contrary is particularly well suited to predict the behavior of a complex process with multiple inputs and outputs such as DED. A significant amount of data is required to train machine learning models, but experimental data are costly time-wise and should therefore be produced in an intelligent way. As a stepping stone for the future production of experimental training data, a finite element model of the process was developed in this study as an unlimited source of training data for the ML models. This model takes into account the printing parameters (laser speed, laser power, and powder flow rate) and outputs’ simulated process monitoring data thanks to a postprocessing method that is outlined in this article. A dataset was produced by simulating 102 tracks in 316L stainless steel with the model. From the analysis of this dataset, it was shown that K-nearest neighbors, support vector regression, decision tree regression, linear regression, and artificial neural network models are all capable of modelling the relationship between the printing parameters and the melt pool characteristics effectively.

Copyright

This article may be downloaded for personal use only. Any other use requires prior permission of the author and AIP Publishing. This article appeared in the Journal of Laser Applications 33, 042052 (2021) and may be found at https://doi.org/10.2351/7.0000526.