Prediction of Melt Pool Temperature for DED Using Supervised Learning Methods on Optical Measurement Data

Charles Snyers, Julien Ertveldt, Jorge Sanchez-Medina, Zoé Jardon and Jan Helsen

Published in Progress in Additive Manufacturing 2021, 2022

Find the full article here.

Abstract

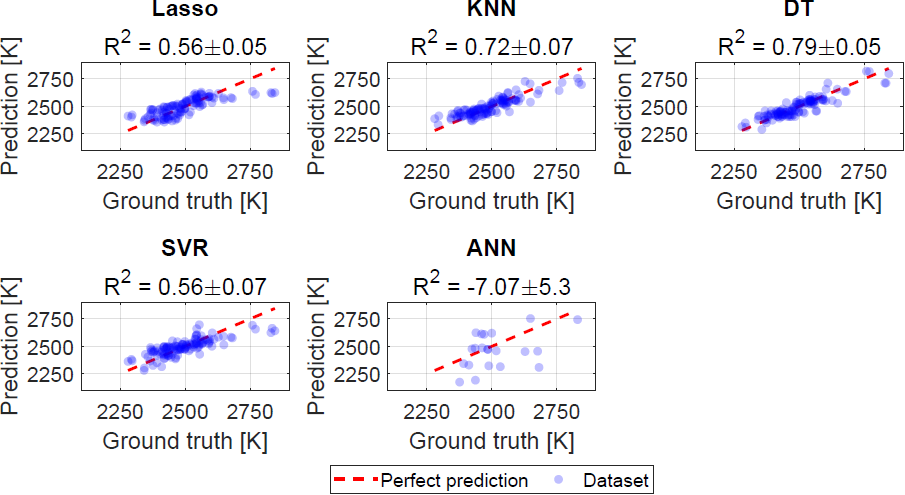

One of today’s ongoing challenges in Directed Energy Deposition is controlling the geometry and material properties of parts. The objective of this paper is to investigate the relationship between several printing parameters of Directed Energy Deposition (laser power, laser speed, powder feed rate) and the melt pool temperature. As Directed Energy Deposition is a complex and non-linear process, well established Supervised Learning models such as support vector regression and artificial neural networks are particularly well suited to represent it. The MiCLAD machine, designed at the Vrije Universiteit Brussel (Belgium), is equipped with a hyperspectral camera that is monitoring the light emitted at several wavelengths by the melt pool during the building process. A steady-state dataset produced by the hyperspectral camera is post-processed by an advanced temperature estimation method and the limitations of the temperature estimation method are identified and discussed. The temperature data is used as training data for Supervised Learning methods and a study is conducted to compare the performance of the considered methods using the measured optical data. This study demonstrates that the melt pool temperature of the Directed Energy Deposition process can be effectively modelled through the printing parameters thanks to Supervised Learning methods.